The Call From Sesame Street Workshop

I was knocked over with a big yellow (patented Big Bird color) feather when I hung up the phone August 12, 2018. The call was from Sesame Street Workshop asking me to make a one-off cuckoo clock for the retirement of Caroll Spinney, Big Bird and Oscar the Grouch’s puppeteer.

My web site, The American Cuckoo Clock Company, generates inquiries for custom cuckoo clocks quite regularly. The calls usually boil down to asking me to make a clock depicting a sports team or singing a famous song or adding something funny sound for a cuckoo. All things we can’t do, so I’d had to sadly dash their dreams.

This call was different. After chatting for some time about clocks the caller remarked about what a dream job I have. I replied that my remaining dream is to meet Ernie and be on Sesame Street, adding that I’m closer to that possibility since a dear friend is friends with Ernie’s new puppeteer and that we had exchanged rubber duckies. She said, “Yes, Peter Linz. I’m calling from Sesame Street Workshop.”

It was then that she shared the purpose of her call. Mr. Spinney and his wife built a Bavarian castle and dress in traditional German clothing, so a cuckoo clock for his retirement gift was a perfect fit. Thanks to Google it was to become a reality!

The Design

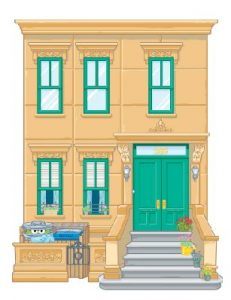

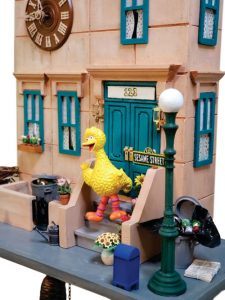

We decided that the clock would be the stoop, the dial up high, and that both puppets would be animated. To help me, the good folks at Sesame Street Workshop sent me photos and the official drawing of the famous Sesame Street Brownstone. Talking about magic arriving in your inbox!

Creating the Famous Sesame Street Stoop in Miniature

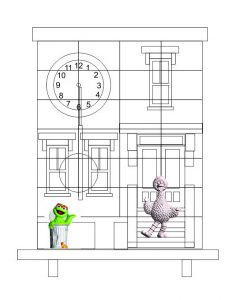

From the get-go Mark and I knew the unusual location of the dial presented challenges for any animation. But we would not be deterred. Oscar and Big Bird simply had to move! The clock had to be the stoop and there was only one place for the dial, so we forged ahead with the design.

I scanned the image Sesame Street Workshop sent me and opened it in CorelDRAW. From that I was able to draw out the front of the building to perfect scale.

Building the Clock Itself

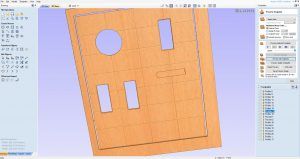

The next step in designing a cuckoo clock is turning the design into tool paths for the CNC machine to cut.

First I save the clock building parts I created in CorelDRAW as a PDF. Then I open VCarve and import the PDF’s. Next VCarve turns them into vector objects which I then tweak to get the layout right for CNCing. Finally I add toolpaths. These are simply straight cuts using an end mill but either in straight lines or rectangular pocket cuts. Thanks to Vectric’s online learning videos the software is super fast to learn. That’s a good thing as I had just bought the Iconic CNC when Sesame Street called!

Even cooler is that VCarve lets you run a simulation of your parts being cut.* That often eliminates surprises when going to the machine to do the real thing because you’ve seen it cut virtually!

*I often post screen captures of the process in my posts on social media. Follow us on Facebook, Instagram, Twitter or Tik Tok at the links at the bottom of the page to follow our cuckoo clock design shenanigans.

Once the pieces are cut I tape them together to make sure they fit. It took a couple of rounds to get things just right. It was such a pleasure to see the clock finally take the shape of a clock!

Next I designed the windows and front door in Vectric’s VCarve software and cut them on my Axion Iconic CNC. Then I cut the stairs using my bandsaw. And cut the shelf the brownstone will sit on and will hold those wonderfully iconic items on Sesame Street: the light post and sign, postal box, and Oscar the Grouch in his trash can!

Finally, time for paint!

It was quite a hoot asking for help at Lowe’s. “Excuse me Sir, but could you help me? I need to match the color of the Sesame Street Brownstone to make a cuckoo clock.”

Turns out getting a color right for a miniature building is no different than for one’s home. It took three trips to get the right color. Three cheers for small paint samples!

Here you can see the trim added, at the top of the clock and above the windows. I primed the clock first to give it a brownstone-like finish.

Animating Big Bird and Oscar the Grouch

Now to address the lump in my throat. With the figures painted, the movement and bellows installed in the clock case, it was time to to install Big Bird and Oscar and get them animated.

The distance of the puppets from the dial necessitated longer wires to connect the figures to the movement — the power — than were available from cuckoo clock parts supply houses. And so, off we went on a mission to find appropriate wire. Easy, right?

No. I ordered wire from several suppliers and even sent a piece out to be tested. No one could tell me, “It’s a something-or-other steel blah-blah with a thickness of X.”

Cuckoo wire is a perfect combination of strength and flexibility. Obviously a rare breed. We finally found a wire that was difficult to bend, but would hold its shape. It would get the job done. Hours and hours and days eaten up. Forward ho!

Creating Big Bird and Oscar

Now for the big question: How are we going to create the stars of the clock? It made me queasy to even think of sculpting Big Bird and Oscar the Grouch myself.

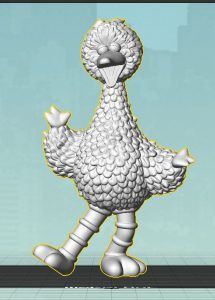

After a discussion with the folks at Sesame Street Workshop two STL files landed in my inbox. Aha! We’ll 3D print them so they are just right!

I sent the files off to my 3D print magician friend Rick Chatwell. (Asking permission first. Man, having that intellectual property on my computer was a big responsibility!) Rick printed them in wood PLA.

We ended up having to break Oscar apart. He was designed in one piece, but we wanted him to pop out of the trash can. So Rick made adjustments and reprinted him. We made the trash can one piece, his head and the lid another. This allowed us to attach the trash can to the cuckoo clock shelf and have Oscar himself pop in and out. Much more realistic than the one piece hopping up and down and the wires (remember them?) were happier. And it looked oh so Oscar!

The good news was that the movement for both characters, even with the distance of the wires, supplied enough power to make our beloved friends do their thing. Whew!

Final Touches

That solved, it was time for the fun items on the street on Sesame Street.

First I needed to make Oscar’s enclosure which I cut with my bandsaw from locally grown poplar. Then I designed the gate in CorelDRAW and had Paul Barney cut it using his laser.

Rick Chatwell designed and 3D printed the iconic Sesame Street street sign. And the mailbox.

More painting, including the curtains inside the windows and the items Rick made.

I scoured the internet (thank you Google!) to find the trash can, flowers, window box, ball, and other items.

It IS Sesame Street!

I felt I was on the hot seat the entire time I was making the clock. It was so incredibly important, a test of my new cuckoo clock making skills. But the moment I put the street sign, Big Bird, and Oscar in their places my reaction was, “This is Sesame Street!”

Turns out, I’m a way better cuckoo clock designer than I ever was a quilt designer.

From Quilt Professional to Cuckoo Clock Maker

You might be asking about now, how did you get into making cuckoo clocks?

Feeding new designs to Germany made for slow progress. Needing product to sell I taught myself woodworking and clock making and put a team together to become our own supplier. That’s about the time I received the phone call.

How’d I become a cuckoo clock designer? It wasn’t exactly a straight line. In 2006 when my book Rubber Duckie had sold over 100,000 copies (ultimately twice that), I was looking to produce a Duckumentary. The producer I contacted heard me say I had written dozens of quilting books. Long story short, that landed me at QNNtv.com an online channel for quilters with me hosting the shows.

Bernina sent us to Switzerland to shoot an episode of one of the series I was hosting. I arranged to shoot an additional episode in a cuckoo clock factory. When cameras were about to roll, I suggested that we turn the chalet with the hag with the rolling pin into a quilt shop and a nice quilter rotary cutting. They bit! To have one for myself I had to import 100. Fortunately, I wasn’t the only one who wanted a Quilt Shop Cuckoo Clock.

When QNNtv.com was bought by F+W in 2014 it was time to reinvent myself. Quilters had been pleading with me to import more Quilt Shop Cuckoo Clocks, so I ran a Kickstarter and sold 77 clocks! A business was born.

Ernie Called Me at My Wedding

Remember how I wrote above that my dream is to be on Sesame Street? Well, I might be a little closer.

Mark Rowell and I were married in my barn last November. At the reception afterwards my dear friend Ivan (who was the videographer back in 2006 when we filmed at the cuckoo clock factory in Germany, inadvertently starting this business) handed me his phone. It was Ernie, as in Ernie and Bert, calling me! The Rubber Duckie’s biggest fan! My hero! It’s a blur, but I am sure of one thing: he said he looks forward to meeting me when I visit Sesame Street.

Commission Cuckoo Clocks

It was my absolute pleasure and greatest honor to make a cuckoo clock for Mr. Spinney’s retirement. And a big bonus that it was the first clock I designed and made here at the farm in Georgia!

The question I’m asked most often is how long it takes us to make a cuckoo clock. Creating a new design soup to nuts is a lengthy process. For our production clocks once the design is worked out and perfected that’s easy. I’ve got spreadsheets drilling down to the time it takes to accomplish each detail. But for a new design the development takes the time it takes. They require so much thinking and research and trial and error. Hundreds of hours for sure. So commissions are few and far between.

Back to work on production clocks!