Cuckoo Clocks Made in America

To use a present day analogy, my path to becoming a cuckoo clock artist is like using an app such as Waze to find a better route. You set off merrily on a direct route, only to come across bumps and even road blocks, that require maneuvering. Inevitably, you get to where you need to be. Even if it is via the unintended scenic route.

Jodie Davis the Cuckoo Clock Designer

A Cuckoo Clock Designer? Now that’s a claim to fame! In high school, when the guidance counselor asked me what I wanted to study at college, Cuckoo Clock Designer certainly wasn’t on the list of choices. Nor Rubber Duckie Designer, nor Quilting TV Show Host for that matter. Had I stuck with electrical engineering people who know me wouldn’t, as is often the case, have to ask me to explain to others what it is I do. What would be the fun in that?

The first time I remember seeing a cuckoo clock I was well into adulthood. A fancy Swiss chalet clock complete with music and dancers and dogs –oh my! – cast the cuckoo clock spell upon me. Between rubber duckies and cuckoo clocks my eBay rating skyrocketed. As is always the case with me, soon I was struck with the make-my-own-bug: I wanted to design a cuckoo clock. Make that “needed” to.

Realizing the Quilt Shop Cuckoo Clock Dream

Back in– gosh, 2006 was it? — the opportunity arose. I headed off to the Bernina Sewing Machine Company in Switzerland with a producer and cameraman to shoot several episodes of a TV series for quilters I was hosting at the time. “So, let’s see… That’s real close to Germany… How do I knit together quilting and cuckoo clocks and turn it into a show? Design a cuckoo clock for quilters of course!”

There was one itsy bitsy problem. My German distributor contact here in the States didn’t think the folks at the factory would get as excited as I over the idea. Regardless, off we went, an American TV show taping a story on the making of cuckoo clocks seemed to be enough for the Schneider Cuckoo Clock factory to put out the welcome mat.

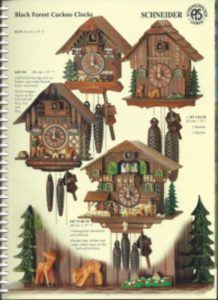

This page from the Anton Schneider catalog shows clocks similar to the one we used as a starting point for that original design, the Quilt Shop Cuckoo Clock.

Changing the old woman to a contemporary quilter was a simple matter for the resident wood carver. And since the woman was already animated, adding a table for her to cut on was no problem. But what about that rotary cutter she needed in her hand? The German-speaking wood carver had no idea what a rotary cutter is, and I hadn’t a clue as to how to translate it, until one of us said, “pizza cutter!” He disappeared and reappeared a few moments later having carved a cutter that needed just a few tweaks to go from pizza- to fabric-ready. What language barrier?

With limited time, we finished taping the show with a cobbled together first rendition of the clock for our “ta da” moment of the episode. That night in the picture-perfect alpine cross country ski lodge, snuggled in a bed that looked like one from my dollhouse, I could hardly believe what had transpired that day.

Back at home the work began to produce the clock for real. I set about creating detailed drawings for what would be the real clock. I sent photos of cutting mats, bolts of fabric, and a rotary cutter to help them get everything quilterly accurate. And… A Quilt Shop Cuckoo Clock Needs Quilts! What would a quilt shop be without quilts? The spaces to the left and right of the cuckoo door provided the perfect spots for two quilts. And an excuse to play around in Electric Quilt to design them. It’s amazing to look back at this and see how much the clock really does look like the drawings I sent!

It’s a Quilt Shop, It’s a Cuckoo Clock, It’s a Quilt Shop Cuckoo Clock

With all the details set I awaited the arrival of the sample clock. It knocked my socks off! With a few tiny changes we pushed the go button on production, ordering 100 of them. As they were manufactured and shipped, I wrote checks and held my breathe that other quilters would be nutty enough to think the combination of a quilt shop and a cuckoo clock was enchanting. Turns out they did and I didn’t end up with 99 clocks in my basement.

Dreams do come true!

The Cuckoo Clock Designer

Fast forward ten years. The internet channel for quilters had been eaten by yet a bigger fish. Time to reinvent myself.

Over the years quilters had been asking when I would import more Quilt Shop Cuckoo Clocks from Germany. To see if they would really buy one I ran a Kickstarter. Seventy-seven clocks sold in just three weeks. Aha! I had a business!

I was fortunate to place the Quilt Shop Cuckoo Clock in the Keepsake Quilting catalog. It did extremely well. I thought, “Hum, if I had two designs, three designs…”

Soon I had submitted designs to the manufacturer and was even invited to the Anton Schneider factory in Schonach, Black Forest to work them out!

Unfortunately for me, business was booming in Germany. New designs were slow to get through the pipeline. It took two years and 36 days to get the prototype for The American Barn Cuckoo Clock.

What’s a girl to do?

I taught myself enough woodworking skills to create my own prototypes thinking I would then send them on to Germany for them to copy and produce.

Then I thought, why not make a small batch of clocks here?

From Cuckoo Clock Designer to Cuckoo Clock Maker

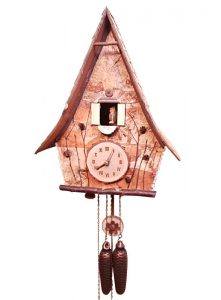

Walter King fired up his humongous CNC machine and cut a couple of sheets of beautiful Baltic birch plywood into neat case parts.

Paul Barney of Lasting impressions turned poplar boards I had planed into trees and birds and friends for the decorative parts of the clock. While his wife Andi and I were talking business (hers, The Sewing Doc, is super smart and timely) Paul had layered the parts according to my diagram. Andi and I turned around and gasped. Even with no color the clock sang!

Back at home I went to work painting, varnishing, and assembling my first Birdwatcher Cuckoo Clock. The sound of my pancake air compressor that powers my staple gun and pin nailer became as common as that of the planer on the farm.

With parts I ordered from Ronell Clock Company and Black Forest Imports, I dove into the clock works. My time with Keith Seabolt, clock doctor extraordinaire, showed as I surprised myself with each step, ending up with a fully functioning cuckoo clock!

When I arrived at Keith’s shop to show it to him he was absolutely quiet at first, turning it around and looking at it.

Then he asked to photograph the clock. “I think he likes it!” I thought.

After a bit he said, “From the moment you walked in the door years ago I knew you could do this.”

Mind you, I had a long way to go still to become a cuckoo clock maker, but it suddenly struck me that it was the route forward: to be our own source of supply.

American Cuckoo Clock Artist

One of my wisest moves was a suggestion from my friend Zach Manring of Southern Woodworkers. I bought a small Iconic CNC. Now, rather than send drawings to him with his mid-sized CNC, or to Walter King and his commercial CNC and have them make test boxes, I could design and make trial boxes and clock parts here to perfect prototypes.

The first cuckoo clock we completed was made entirely on that router. It was a commission for the retirement of Big Bird and Oscar’s retirement. What an honor!

The many tools and steps in building cuckoo clocks now took over more and more of the farm. The woodshop is in the tack room; painting, assembly, and clockmaking in my big, bright basement; and my living room is a gallery. My contemporary house and barn (which I designed) are a fitting home for creating the modern cuckoo clock.

One day it struck me that this is exactly how it happened in the Black Forest 250 years ago, an inadvertent repetition of the original cuckoo clock story!