How We Make Our Cuckoo Clocks

When I started, there was no one in America who could teach me how to make a cuckoo clock. The skills involved include woodworking and clockmaking. Plus a whole bunch of others required to make my visions become reality. One foot in front of the other I set off.

To learn the mechanical part clock repair guru Keith Seabolt gave me some old movements and bellows to tinker with. I spent hours researching, reading, and playing with those parts. Here he is early on showing us how to put a cuckoo door in one of our designs.

As for making the cases — the woodworking skills, what tools and materials to use, what size and distance and width holes for chains and everything else — I simply had to start making clocks to figure it out.

Many people, You Tube videos, Facebook groups, and just plain studying cuckoo clocks helped me get there. I had just met my now-husband, Mark Rowell, who helped me through learning what tools do what and how to use them.

It Starts with a Cuckoo Idea

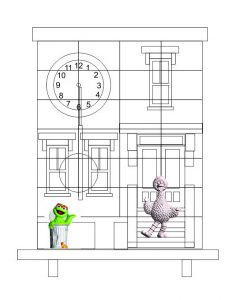

Most often I amass a bunch of images to start creating my idea. With the Sesame Street Cuckoo Clock Sesame Street Workshop supplied me with a drawing of the famous stoop brownstone once that’s the direction we decided to go. It was easy to scan into Corel Draw and start designing.

I made a line drawing, then transferred that to Vectric V-Carve to create toolpaths for the CNC to cut it out.

The parts fit. It’s beginning to look like the neighborhood!

Some clocks start as a plain box with just a general idea in mind. For example, I had an idea which way I was going for the Bell Cuckoo Clock, but plans changed and it ended up looking like a Victorian Chapel. Exactly as when I was making quilts, the clocks tell me what they want to be.

The Cuckoo Design Process

For some clocks the design is all planned out before any wood is cut. The only decision left for this Log Cabin Quilt Cuckoo Clock is simply paint color.

Which is great because customers can choose what they want!

And then there are the times when it’s incredibly difficult to find the best way of doing something. These are just a few of the tries I made at the Double Wedding Ring Cuckoo Clock before I figured it out. The answer was a puzzle.

The Many Skills We Use in Our Clocks

Before the actual clockmaking process, there are many skills I use to make the clocks come to life. I’ve learned whatever I’ve needed to learn along the away. And made some sweet little things as a result, such as these owls.

I studied and tested all of the aspects of finishing: sanding, staining, painting, dyeing, sealing, etc. Markle even figured out what the Germans use to get a glass-like finish on their cases.

Woodcarving is one of the techniques I use to make the figures for my clocks. After looking for woodcarvers I thought it would be much easier if I could do it myself. The first step is to cut out the shapes with a bandsaw (rough cuts) or a scroll saw (more finished pieces).

I started with simple things like nearly flat animals and am working my way up. Unlike sculpting which I had done before, with woodcarving you can’t easily put wood back when you’ve taken it off!

For little figures I often sculpt, scan, and then 3-D print. Here’s the eagle for the cuckoo for the Old Glory Cuckoo Clock. When printing him I can make him any size I wish.

This is the eagle in the Old Glory Cuckoo Clock. Of course the cuckoo had to be an eagle!

The clocks present an endless opportunity for learning. For my original Golf Cuckoo Clock I was working with a company that makes products for golfers. The print images on wood, so we went that route.

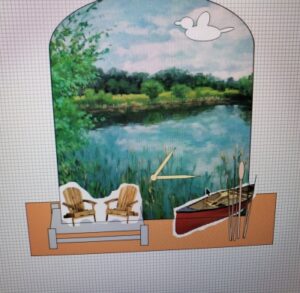

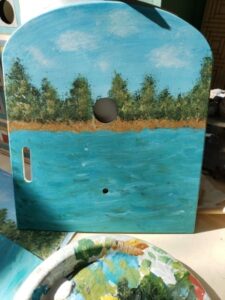

When I turned to making the lake clock I started looking at images to use to print the fronts and thought, ” It doesn’t need to be fine art. It’s just a background. I can paint that!”

I spent time watching You Tube videos and trying the artists’ techniques, then playing on my own. The result I thought was way better than a printed image. I’m a cuckoo clock artist, not a painter, but I am pleased with the results!

Sourcing materials has been quite an experience. I have even made new friends in doing so. I started out using bark from a river birch on my farm, but soon discovered I needed a better solution. I found a birch bark canoe maker who sources his bark from Alaska. The nice straight twigs for the side of the Hickory Flat Cuckoo Clock come from a high end furniture maker in upstate New York who grows and coppices the willow shrubs for his creations.

Time to Become a Cuckoo Clock Mechanic!

With the case completed it’s cuckoo time! The next step is to make the clock and clock, installing a movement, bellows, pull down, cuckoo and (on most) cuckoo door.

As I started assembling my first clocks I would take them up to Keith and ask for his honest input to improve them. I wasn’t long before I needed less and less help.

It was about that time that my then new husband Mark took an active roll in taking on the mechanical work. Every time I came upon something that needed perfecting he would disappear and after soon have figured it out. His level of attention to detail is tremendous. And he can make just about any little parts we need. We truly are a great team with complementary skills.

We import the Regula 8-day movements, bellows, and small parts for our clocks from Germany. These parts are made as they have been for generations by family businesses.

Almost Home!

Each of our clocks is run and tested for a number of weeks to make sure it is keeping time and that any animation is working properly. We hang the clocks in my living room, so we get to hear them cuckoo. I often hear Mark chuckle when he hears one we just created. Bringing them to life is such a joy!

It seems ridiculous, but it takes me well over an hour to box a clock. I want the clock to arrive in perfect shape.

Honestly, I hate to see them go. But I love knowing the smiles they will bring in their new homes. We’re happy when we here the clock arrived safely. Marks such a cool cucumber, but even he worries about them going off into UPS land!

Give us a holler if you’d like us to craft you a cuckoo clock!

~Jodie Davis (Rowell) and Mark Rowell